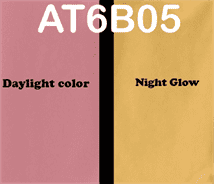

Description

-

- WHAT ARE GLOW PIGMENTS?

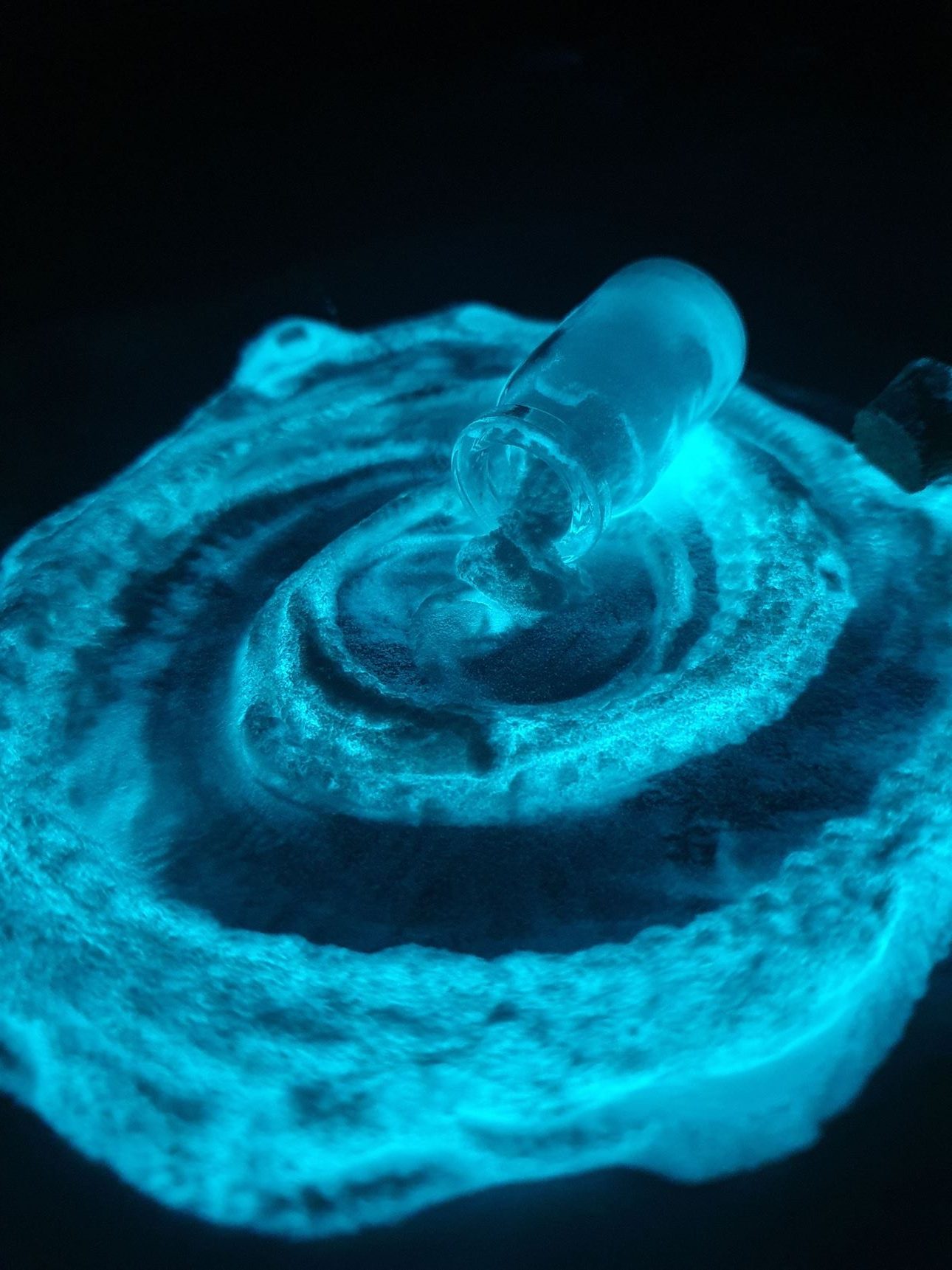

Our long lasting glow pigments are manufactured using the very latest in cutting-edge technology to deliver a self-illuminating light that recharges indefinitely.

Unlike light reflectors, this product offers an eco-replacement to electricity with its self-rejuvenating and sustainable output of ambient light.

The pigment will absorb energy (UV) from conventional lighting and sunlight and will then emit it slowly over a 8 to 10 hour period.

We believe this product is the best glow pigment on the market. If used correctly, this product will not disappoint.

Product name: Photoluminescent pigment

Chemical name: Dialuminium x dysprosium y europium (1-x-y) strontium tetraoxide

Synonyms: Alkaline earth aluminates (europium-doped)WHAT CAN GLOW PIGMENTS BE USED FOR?

Glow in the dark pigments can be used for thousands of different applications, including road signs, special effects, fashion, health and safety, arts and crafts, jewellery design, automotive coatings, toys, stickers, clocks and watches, fire exit signs, pathway markings and Halloween products.WHAT CAN I MIX GLOW PIGMENTS WITH?

Our glow pigments can be mixed with non-water based mediums, including clear resins, PVA glue, paint, sealers, clear coat, varnish, lacquer and inks.

It is always recommended to add your chosen medium to the glow pigment rather than the pigment to the medium.

Try to avoid making large batches.Make the product as and when you need it to prevent the particles settling. Always remix the coating before reusing.

If possible, please use a viscous (thick) medium. The glow particles are heavy than water and tend to settle rather quickly.Please avoid using coloured mediums when producing a glow in the dark coating. A transparent medium is needed to increase the brightness of the glow.

When mixing the glow pigment in with your chosen medium, please avoid grinding or sheer force as this can damage the crystals and destroy the glow.HOW MUCH OF THE GLOW PIGMENT SHOULD I USE?

Mixing ratios can be adjusted depending on the application.

Please check what is recommended by the manufacturer of the medium you are using.

For example, If you are mixing the glow pigment with clear resin you can ask the resin supplier how much of the pigment can be added.

10% pigment to 90% medium is usually sufficient. For example, 10 grams pigment to 90 grams medium.

WHAT CAN I USE TO MIX MY PIGMENTS?

We recommend using plastic spatulas and mixing bowls. Please avoid using metal mixing equipment as this could react with the glow pigments.WHAT SHOULD I USE AS A BACKING COAT?

For the best results, it is always best to apply the finished glow coating to a light or white background or basecoat.A dark background or basecoat will deplete the glow.

Please avoid using coloured mediums when producing a glow in the dark coating.A transparent medium is needed to increase the brightness of the glow.

The medium used must also have low acidity.

HOW SHOULD I APPLY THE PIGMENT?

If you have made glow paint or glow varnish you can apply this using a brush or a paint roller.

A heavier build (coating thickness) is required to increase the glow time and brightness. A thin layer of glow coating will not perform as well as a thick layer.

2-3 coats may be needed to increase the glow

Always ensure the coating is applied to a dry surface that is free from debris.

Once the coating is dry, please use a clear protective top coat to give it extra durability.

For example, If you have mixed the glow pigment with a clear solvent based varnish, you can use a coat of varnish to protect it.

Please check the manufacturers TDS of the medium you are using, this will give you curing times and further information if you are using resin.

The information supplied in this product description is designed only as guidance.This information is correct to the best of our knowledge and belief at the date of publication, however, no guarantee is made to its accuracy.

Please thoroughly test this product before beginning final projects, print runs or production.

- WHAT ARE GLOW PIGMENTS?